Safety is in the handle, not the blade.

In 1976, MARTOR USA began the quest to prove that statement through tireless work, experiments, and studies.

The result?

The Zepher Model 102, a one-of-a-kind safety cutter designed to cut through anything while keeping your fingers safe.

Now, four decades later, MARTOR USA continues to be on the cutting edge of safety knife technology by developing stronger blades, more ergonomic handles, and better protection against accidental slices.

What is a Safety Knife?

A safety knife is a spring-loaded knife with a self-retracting blade. Frequently used in warehouses and factories, safety knives are designed to cut through cardboard, layers of film, or paper from a roll.

But the biggest difference between your traditional kitchen or pocket knife and a safety knife is how the latter prioritizes employee safety as much as cutting ability.

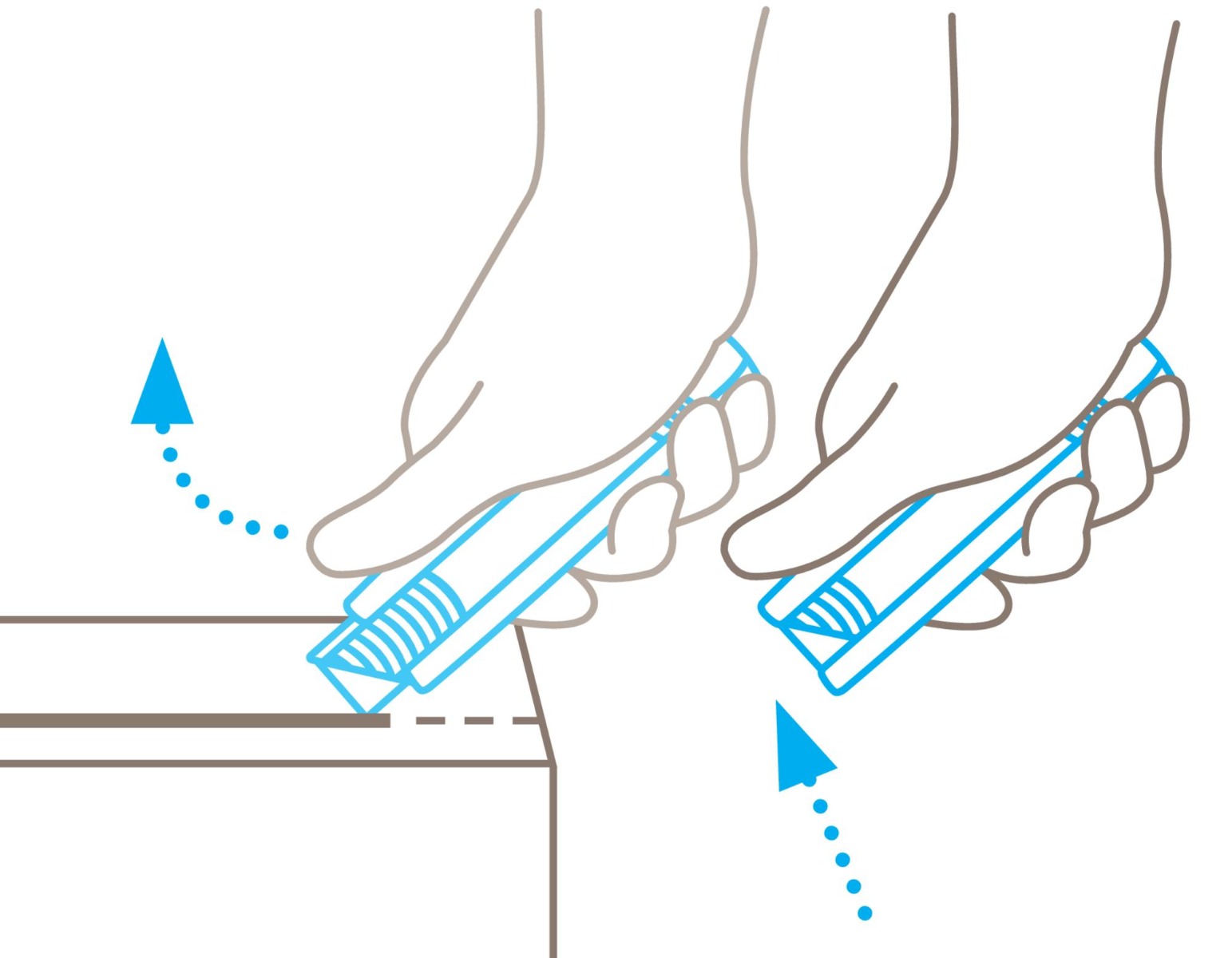

We used our knowledge and experience in the safety knife world to create a 5 Level Safety Knife Guide that ranks our products from maximum safety to basic safety.

Work injuries account for around $45,000 per laceration in direct and indirect costs. With fully functional, well-developed retraction methods, a good safety knife (and proper training) avoids unexpected and unwanted expenses.

We spent decades perfecting the safety knife. MARTOR is proud of our innovative safety knife lineup through rigorous testing.

MARTOR Invented the Retractable Blade Safety Knife

MARTOR uses a couple of rules when designing all of our safety knives:

Invest in an ergonomic handle to keep your hands safe and fingers comfortable.

Prioritize a high-quality, sharp blade to cut through the most challenging materials.

Build the strongest, most durable final products imaginable.

Over the last four decades, our team of safety knife scientists have designed, deconstructed, and developed some of the most popular safety knives on the market.

Our innovational strength and inventiveness continuously push us to refine our products to last longer, stay sharper, and feel better.

The Safest Safety Knife

Prepare yourself for the safest safety knife on the planet.

The five-level MARTOR safety classifications redefined knife safety.

Want maximum safety? We’ve got it with our SECUMAX series.

Need a little bit more blade and a little less safety? Level 5’s ARGENTAX collection offers basic protection with some of the sharpest blades around.

Our ergonomic handle and advanced retraction technology protect you no matter which level of security and sharpness you need.

Download the printable safety levels chart here.

The Rules of a Fantastic Safety Knife

You will want to use a high-quality safety knife built from the best materials on the planet.

Sharp. Comfortable. Unbreakable.

If your safety knife isn't all three of these things, then you're not using a MARTOR safety knife.

The Right Kind of Comfort

At the end of your shift, the last thing you want is pain or discomfort when holding your knife.

That's why the Hand Comfort Specialists at MARTOR designed our knives with ergonomics in mind.

And it's not just us saying it.

The renowned Nuremberg Institute for Health and Ergonomics (IGR e.V.) recently announced MARTOR as the first knife manufacturer to bear the recognized IGR seal of quality.

Whether it's the beginning or end of your shift, our knives fit perfectly in your hands and offer a smooth cutting experience all around.

A Retraction that's Smoother than Butter

MARTOR not only invented the retractable safety knife, but we've perfected it.

MARTOR safety knives feature three different retraction systems: automatic, fully automatic, and concealed.

Avoid unnecessary cuts with our automatic retraction safety knives. As soon as you start cutting, remove your thumb from the slider, and the blade will disappear into the handle the moment it loses contact with the material being cut.

Get ready for the intelligent cutting tool: fully automatic retraction safety knives. Unlike the automatic knives where you release the blade back into the handle, the fully automatic safety knife does it for you.

As soon as the blade leaves the cutting material, it withdraws entirely automatically into the handle, without you having to do anything.

For maximum safety, check out our concealed blade safety knives. The blade is not open but concealed, shielded from people and goods alike. Giving you a maximum degree of

safety from cut injuries while cleverly protecting your goods.

Flexible Options for Safety Blades

Choosing the correct blade type for your safety knife doesn't have to be a chore.

Unlike other options, MARTOR safety knives offer flexible options for our blades.

Whether you prefer ceramic or steel blades, our effortless blade change housing system makes switching in and out safer and simpler than ever before.

Steel Blades from the City of Blades

Forged from the heat of Solingen, Germany, designed by brilliant minds at MARTOR, and engineered just for you, our steel blades are built to last.

Born from the "City of Blades," Solingen, Germany, every steel blade has been crafted to stay sharper for longer. One test revealed that our competitor's steel blades dulled 4x faster than ours.

Rest assured that if you buy a Solingen Steel Blade from MARTOR, you're guaranteed to be getting the highest quality blade from the oldest, most renowned steel manufacturers in the world.

Ceramic Blades that are Up To the Challenge

Our ceramic blades are made from high-quality zirconium oxide 12x longer than a comparable steel blade.

That means they stay sharper for much longer.

Each ceramic blade features unique chemical and physical properties, including non-rusting, non-conductive, chemically stable blades.

No matter the environmental conditions, our ceramic blades are up to the challenge.

A Nearly Unbreakable Knife

Finally, a safety knife as rugged as you are.

MARTOR takes pride in how durable our safety knives are.

Try to throw them on the ground, drop them off the second floor, slam them into a wall.

It doesn't matter. MARTOR safety knives can handle it.

Sharp. Comfortable. Unbreakable.

Four decades of innovation helped us produce the most ergonomic safety knives on the planet with authentic Solingen blades that last way longer than the competition.

If you're looking for a sharp, comfortable, and unbreakable safety knife, put your trust in MARTOR’s safety knives.

Don't believe us? Try it for yourself with our sample knife program.

Frequently Asked Questions

At MARTOR, we care about our customers’ cutting needs, and we are available to answer any questions that may arise. We pride ourselves on delivering high quality knives, blades, tools, and accessories, and we believe that safety is our business.

MAXIMIZING WORKPLACE SAFETY

SAFETY FOR YOUR EMPLOYEES

A safety knife is a cutting tool for manual cutting work. The built-in safety technology protects users from cutting injuries. When cutting by hand, using safety knives minimises the risk of cutting injuries that can result in absences from the workplace.

SAFETY FOR YOUR PRODUCTS

When you use a safety knife with a concealed blade to open packaging, the packaged goods can also be protected from damage. Some safety knives also offer protection to the items inside the packaging being opened.

USER FRIENDLY TOOLS

In addition to workplace safety, MARTOR attaches great importance to ergonomics and user-friendliness. With MARTOR safety knives, you can work efficiently and comfortably.

MODERN SAFETY TECHNOLOGY

MARTOR safety knives give you the choice between three kinds of safety technology:

- Concealed blade

- Fully automatic blade retraction

- Semi-automatic blade retraction

Safety knives with concealed blades stand for maximum work safety (plus optimum protection of goods), and safety knives with fully or semi-automatic blade retraction are excellent for very high work safety.

SAFETY LEVELS AND TOOL TYPES

WHAT DO THE SECUMAX, SECUPRO, AND SECUNORM TERMS MEAN?

SECUMAX, SECUPRO and SECUNORM are special MARTOR terms. As part of the product name, they provide information about the safety technology used in the product and the resulting safety level:

-

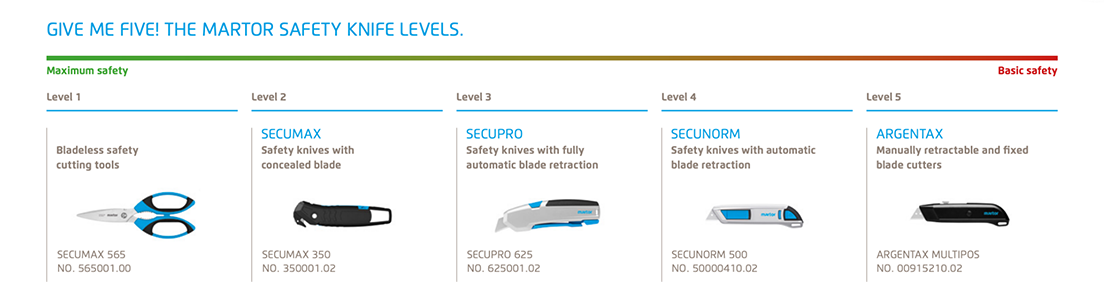

The SECUMAX is a MARTOR safety knife with a concealed blade for maximum work safety.

For example, a MARTOR safety knife with a concealed blade (SECUMAX) has a blade that is so securely concealed that neither users nor packaged goods can come into contact with it.

For example, a MARTOR safety knife with a concealed blade (SECUMAX) has a blade that is so securely concealed that neither users nor packaged goods can come into contact with it.

-

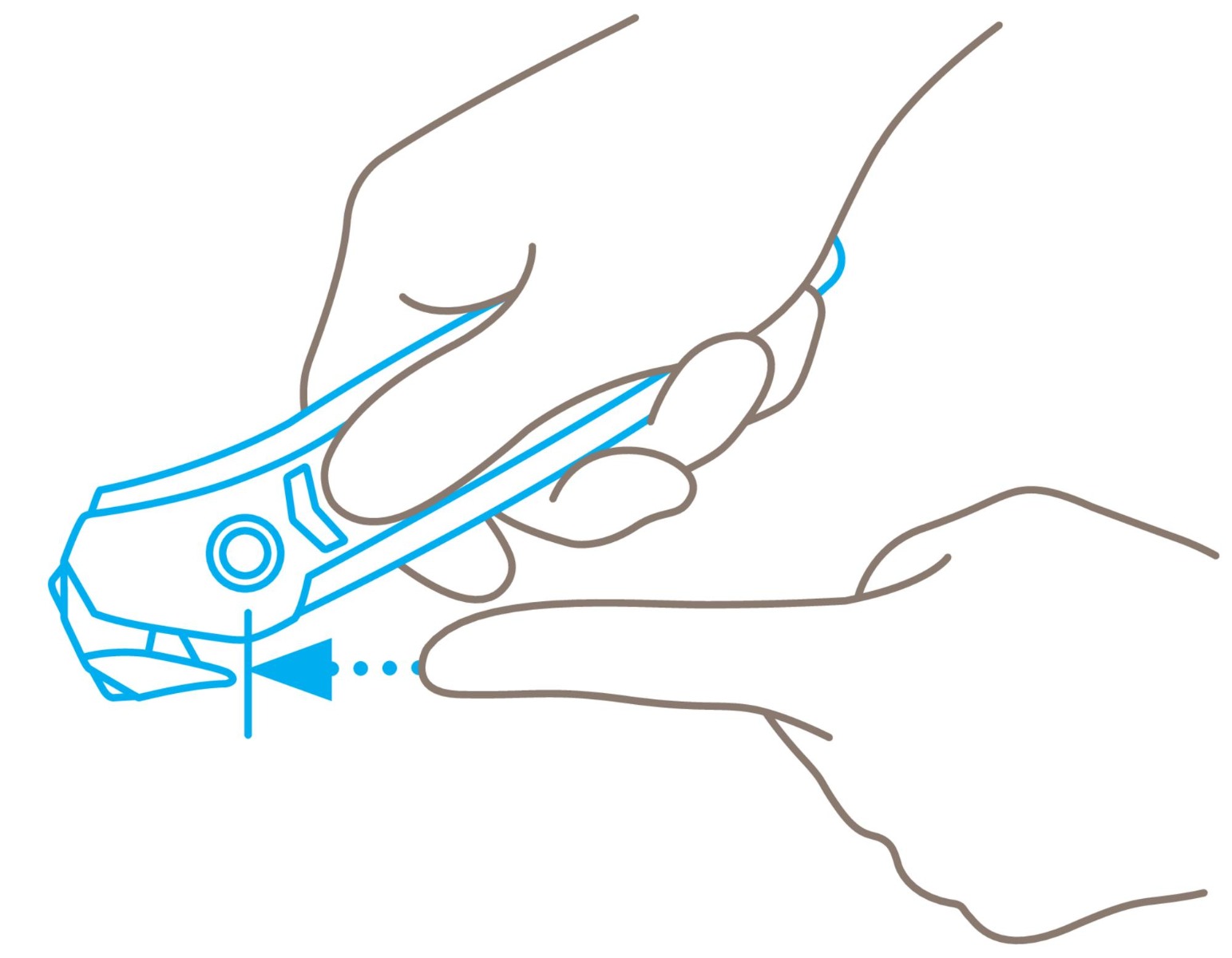

The SECUPRO is a MARTOR safety knife with fully automatic blade retraction for very high work safety.

For example, a MARTOR safety knife with fully automatic blade retraction (SECUPRO) has a blade that instantly retracts after cutting even if you continue to hold the slider or lever that releases the blade.

For example, a MARTOR safety knife with fully automatic blade retraction (SECUPRO) has a blade that instantly retracts after cutting even if you continue to hold the slider or lever that releases the blade.

-

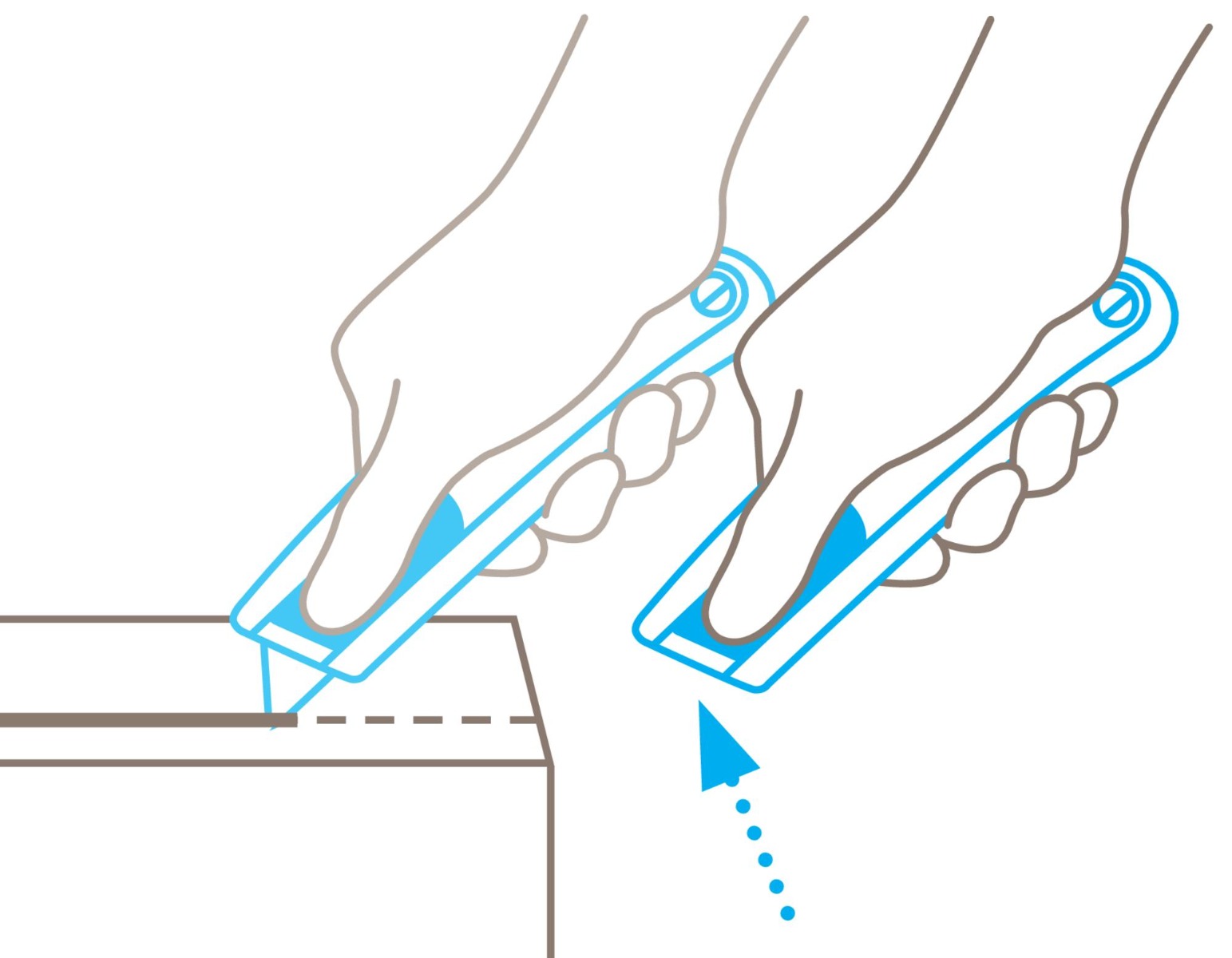

The SECUNORM is a MARTOR safety knife with semi-automatic blade retraction for high work safety.

A MARTOR safety knife with semi-automatic blade retraction (SECUNORM) has a blade that disappears into the handle immediately after cutting as long as you have removed your thumb or finger from the blade release beforehand.

A MARTOR safety knife with semi-automatic blade retraction (SECUNORM) has a blade that disappears into the handle immediately after cutting as long as you have removed your thumb or finger from the blade release beforehand.

In short, all MARTOR knives are built with safety in mind. With SECUPRO and SECUNORM, however, the blade is "out" only for as long as it is needed for cutting.

A CUTTING TOOL FOR EVERY NEED

It is important that packaged goods are not damaged when packaging is opened using a cutting tool. The best way to achieve this is to use a safety knife with a concealed blade. The blade is so securely shielded that no contact can take place between the blade and goods.

WHAT DISTINGUISHES A CUTTER FROM A SAFETY KNIFE?

With a cutter or carpet knife, you cut with a fixed blade that is neither concealed nor retracts by itself after cutting. The risk of cutting injuries is then significantly increased.

WHAT CAN BE CUT WITH A SAFETY KNIFE?

Safety knives can be used for cutting various materials: cardboard, adhesive tapes, film, paper, plastic strapping bands, foam, polystyrene, textiles, floor covering, PVC, rubber, fleece, leather, etc. The relevant MARTOR product page also shows what materials a cutting tool is suitable for. For detailed advice, please contact our knowledgeable safety experts.

IN WHAT AREAS CAN SAFETY KNIVES BE USED?

This depends on the safety knife. Many MARTOR safety knives can be used in a wide range of various applications.

THOUGHTFUL AND USEFUL DESIGN

Some safety knives are recommended for very specific areas. The best thing is to let our experts advise you based on your needs.

WHAT ARE THE HANDLES MADE OF?

They are mostly made of high-quality plastic or aluminium and also zinc in special cases. Many of our handles use a "soft grip" component to make them easier to grip, ergonomic, and slip-resistant.

WHAT DOES METAL DETECTABLE OR MDP MEAN?

MDP stands for metal detectable plastic. If MDP knives or parts of MDP products enter the production process unintentionally, they can be quickly detected by the company's own detectors and filtered out by employees.

MARTOR's MDP knives are specially designed for contamination-prone industries such as the food and pharmaceutical industries.

HOW CAN I KEEP MY SAFETY KNIFE SAFE?

It may sound contradictory but only a sharp blade is safe. A sharp blade enables you to cut with minimum effort, and in a controlled and effortless way. A blunt blade requires more force and can lead to uncontrolled slipping. This considerably increases the risk of a cutting injury.

QUALITY BUILT TO LAST

CAN I REPAIR MY SAFETY KNIFE?

We advise against repairs or modifications to the product as they may affect product safety.

If a cutting tool shows signs of ageing or other wear and tear, e.g. malfunctioning in the safety technology, blade changing or usage, it must be discarded and replaced. MARTOR blades are made of high-alloy carbon steel and hardened to give them the required sharpness. The degree of hardness has been chosen to keep the blades sharp for as long as possible and also as break-resistant as possible.

If a cutting tool shows signs of ageing or other wear and tear, e.g. malfunctioning in the safety technology, blade changing or usage, it must be discarded and replaced. MARTOR blades are made of high-alloy carbon steel and hardened to give them the required sharpness. The degree of hardness has been chosen to keep the blades sharp for as long as possible and also as break-resistant as possible.

However, any blade can be damaged through incorrect or excessive force (especially with so-called forceful cuts). Avoid bending or twisting the blades.

HOW LONG DO THE BLADES LAST?

There is no exact answer to this question. Service life mainly depends on the number of cuts and the cutting material. For example, cardboard with wood fibres is more abrasive than thin plastic film and thus dulls the blade more quickly.

The type of cut, force, speed of the cut and type of cutting surface all influence service life.

HOW DOES MARTOR ENSURE THE QUALITY OF ITS KNIVES?

Product development is located at MARTOR headquarters in Solingen, Germany. Assembly of the products takes place in Solingen. Each knife is subjected to a 100% functionality check before it leaves the factory.

SHARPNESS IS IN OUR NAME

The MARTOR brand name is derived from the marten, a small predatory animal. The name refers to the pointed and sharp teeth of this species. At MARTOR, we want to ensure that every tool we sell meets our highest standards for safety and sharpness.