Did you know that box cutters are responsible for one-third of workplace injuries? Or that 4 in 5 hand injuries are caused by lacerations or cuts? While valuing efficiency is essential for a healthy business, safety is just as important.

At MARTOR, we’re passionate about creating a safe workplace and helping companies everywhere prevent injuries.

Using our decades of safety knife knowledge and professional training expertise, we have put together these box cutter safety tips to utilize in your factory, warehouse, or workplace to prevent unnecessary injuries.

5 Box Cutter Safety Tips

Before preventing box cutter injuries, you need to understand how they occur. Most often, lacerations and other injuries stem from:

- • Using a dull or broken blade

- • Leaving a retractable blade “open”

- • Cutting through extremely tough material

- • Cutting toward the body

- • Cluttered workspace

Preventing injuries and lacerations requires the influence of multiple stakeholders, from the EHS manager and employee to the actual quality of the tools being used.

Employees are far more likely to injure themselves or others while on the job if a workplace provides poor-quality safety knives or does not provide appropriate training opportunities.

These five box-cutter safety tips were developed utilizing our vast experience listening to customers to promote safer workplace practices.

1. Make sure you have the proper equipment

When our engineers develop new safety knives, we always consider safety first. As a business owner or EHS manager, you must think about safety first, which means equipping your team with the right tools.

A safety box cutter needs to be one of the first tools you invest in. One specifically designed to reduce or eliminate injuries is the best way to stay safe. Plenty of generic box cutters on the market don’t provide the safeguards to prevent injuries.

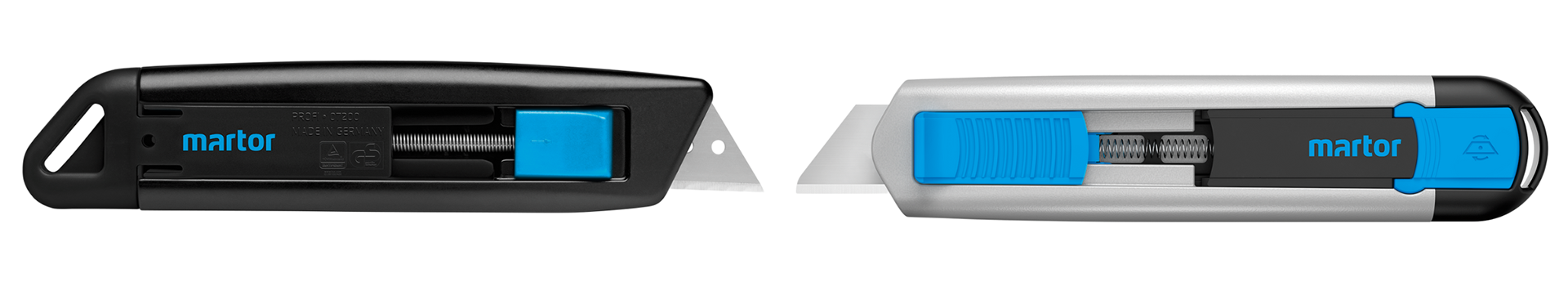

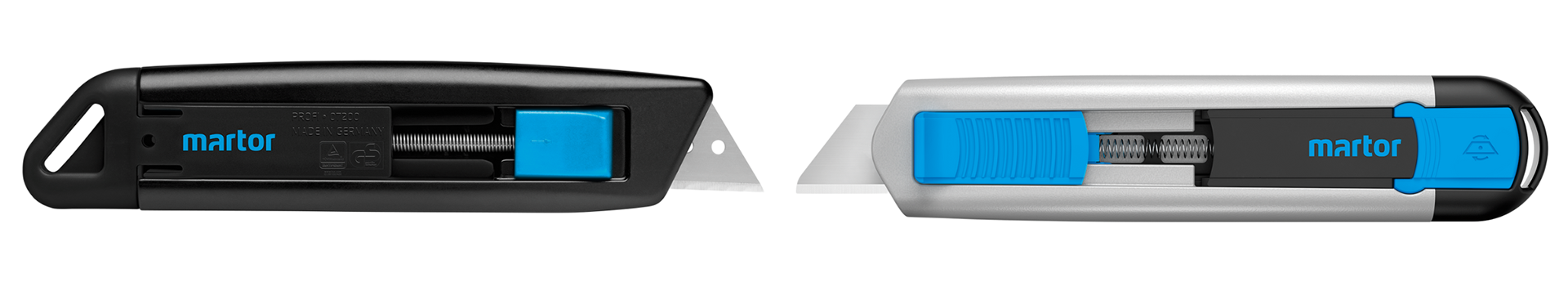

Cutters with a fully automatic retractable or concealed blade are your best option. This ensures that if a user’s hand slips while cutting, the blade retracts, eliminating the opportunity for a laceration.

Another recommended precaution is using protective gloves to avoid nicks or cuts. They also provide a firmer grip, thus helping to reduce the chance of slipping while cutting or opening boxes.

All of the safety knives developed by MARTOR provide ergonomic grips that help avoid hand cramps from occurring.

Finally, always keep a first aid kit on-hand for employees using box cutters regularly in the event of injury.

2. Maintain the integrity of the blade

Regardless of the type of metal a box cutter blade is made from, it must always be pristine. When not maintained, the control of the tool is compromised, and the risk of injury increases.

The most crucial factor is blade sharpness. Sharp blades cut, whereas a dull blade tugs and pulls due to the extra effort required.

Like dull blades, broken blades also require extra strength and lead to more injuries.

Finally, avoid non-stainless steel blades that have begun to rust with age. A rusty blade is a dull blade that poses an even larger threat to users due to the risk of infection. Should a laceration from a rusted blade occur, it should be disinfected and treated immediately.

Beyond bodily harm, a rusty blade or tip also damages the product. When used for cutting, a rusty blade can leave brown marks and streaks on the product’s surface and compromise quality.

At MARTOR, we pride ourselves on not only having the safest safety knives available but the sharpest blades as well. There’s no need to sacrifice sharpness when protecting yourself and your employees.

A good rule of thumb is to avoid using old blades that have dulled, chipped, or broken. In the event of a compromised blade, always keep replacement blades nearby.

3. Always cut deliberately and away from the body

Box cutters are great for cutting through both thick and thin materials. Regardless of the material, their movement must be deliberate with firm, consistent pressure.

What does that look like?

First, it means cutting away from the body. There should never be a reason for a user to cut toward their body, as a single slip or tug could lead to serious bodily harm.

To stay safe, users should cut the item halfway before flipping it and cutting the other half to keep the blade away from the body and reduce slipping.

4. Handle the box cutter safely

All users should be well-versed in how to handle a box cutter safely. Some easy ways to safely handle box cutters include:

- • Always check the blade before and after using it

- • Never leave the blade in the “open” position when not in use

- • If adjusting the blade length is an option, shorten and lock it to avoid injury

- • Keep the thumb of the hand using the cutter away from the blade and your other hand far enough away to prevent laceration

- • Never throw a box cutter, choosing to pass it handle-first instead

- • Never attempt to catch a dropped cutter

By following these simple rules, you’ll immediately eliminate potential dangers.

5. Invest in knife training

If you haven’t already, it’s time to invest in box cutter safety training. This training should range from proper knife usage to instructional first aid guidance. Signing up, attending, or presenting any knife training course is money well-spent because protecting your employees from serious harm should be your top priority.

Over the past 40 years, our team has worked with businesses nationwide to implement life-saving knife training programs. No matter the type of safety knife you use, MARTOR can help.

Learn more about how our training program can keep your workplace safe here.

MARTOR, The Safer Way to Cut

Planning, preparation, and training solve most safety issues. By working with MARTOR, you are provided invaluable safety knife training and customized options to help fit your business.

At MARTOR, we offer a variety of box cutters that keep your employees safe with features such as fully-automatic retractable blades, concealed blades, and ergonomic handles.

Please login to comment.

Don't have an account?

Sign Up for free